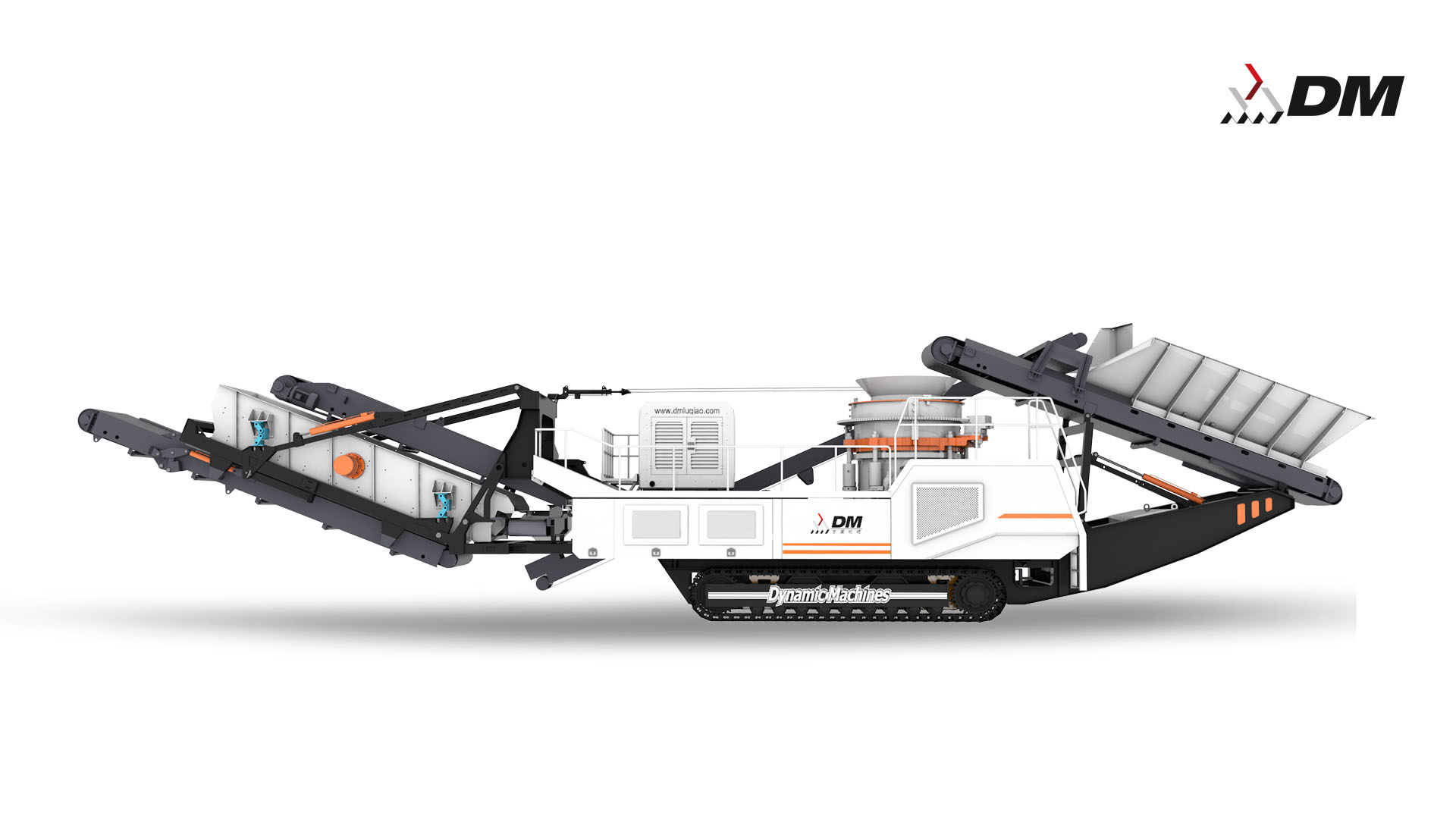

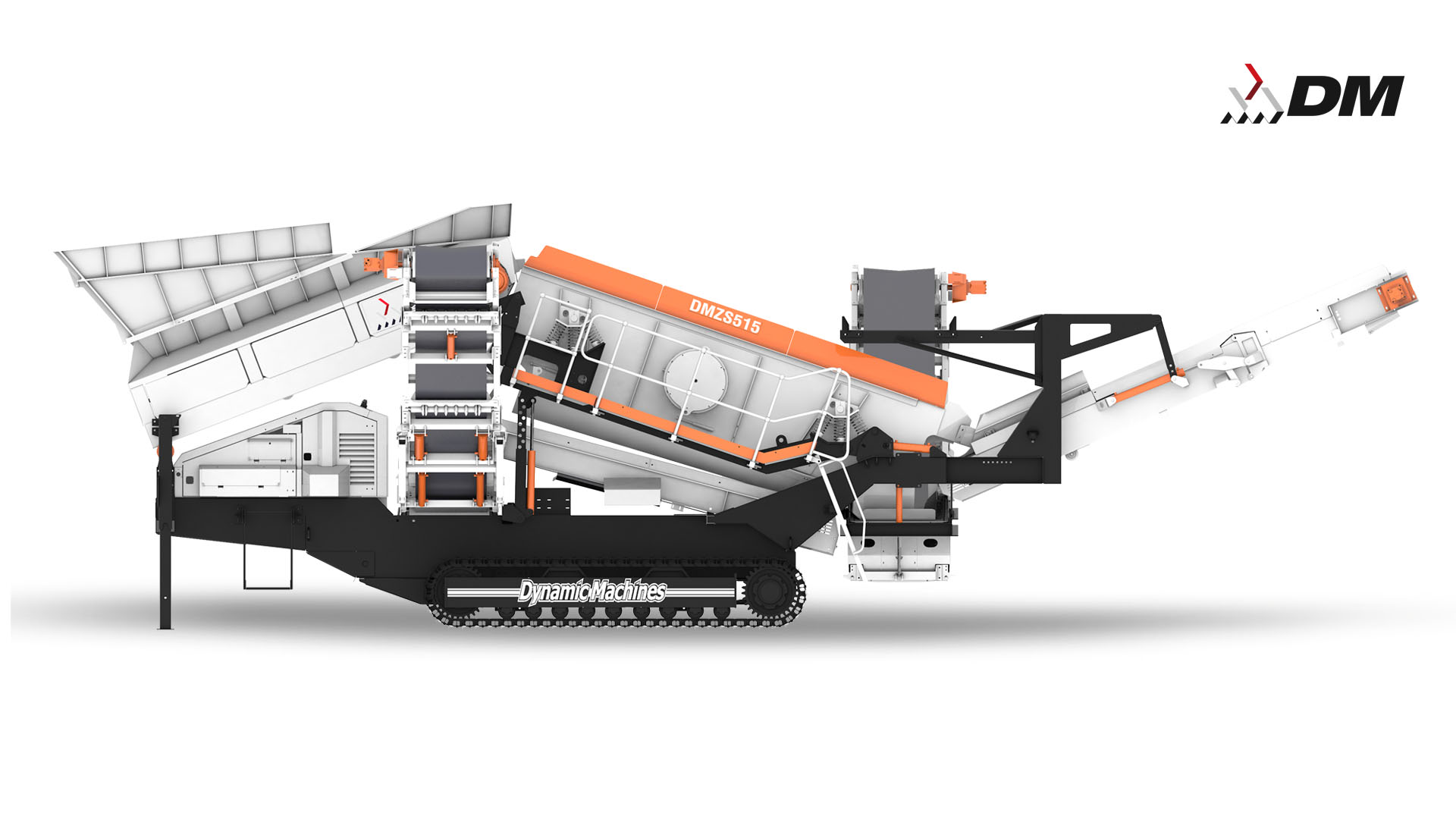

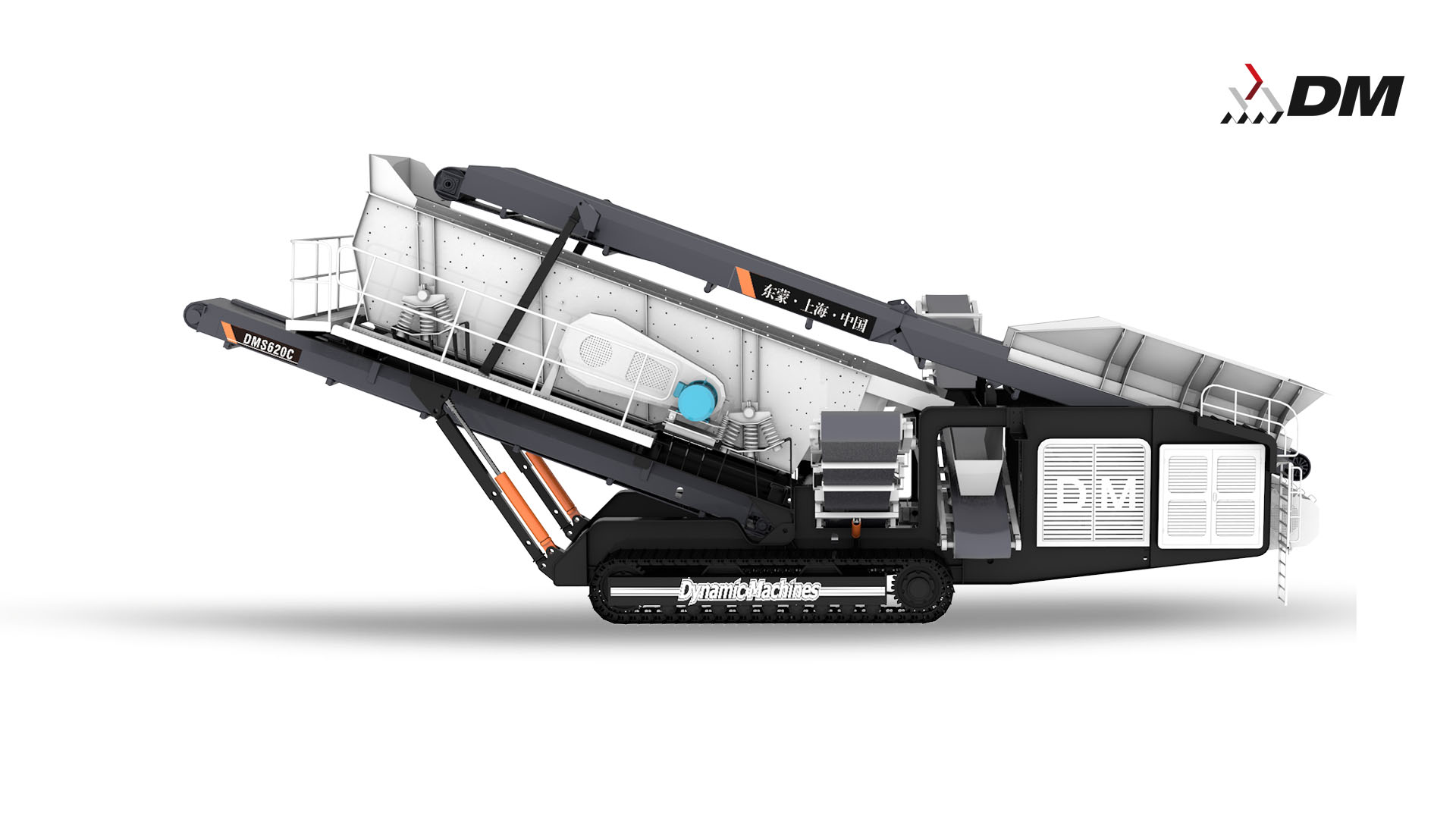

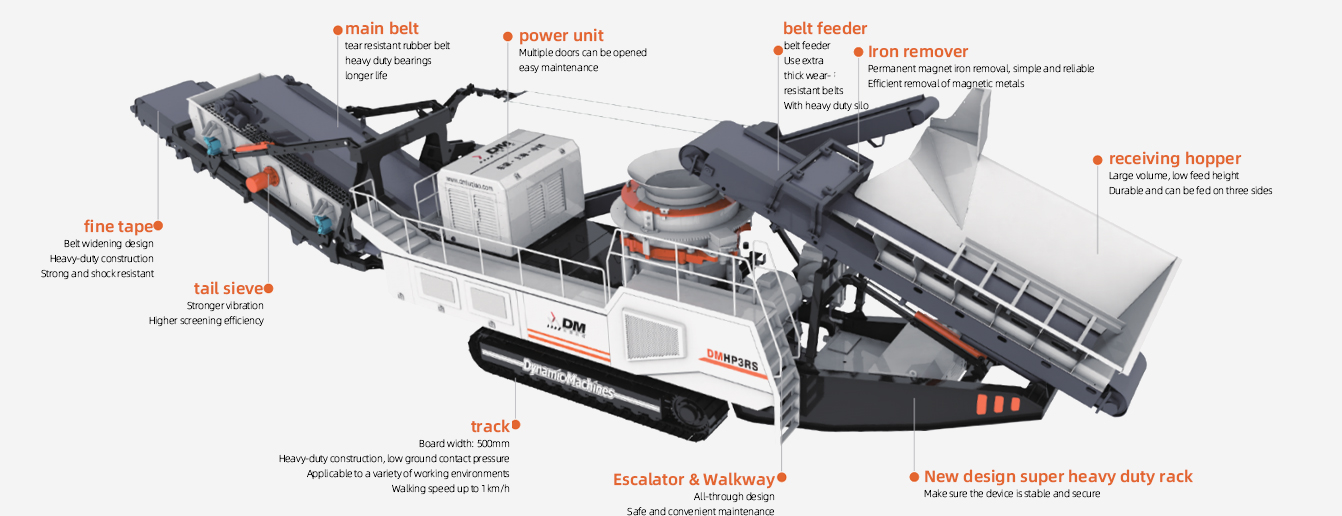

Mobile cone crushing station. According to the customer's requirements for material processing, it matches various crushing cavity types, making it suitable for any application, with the characteristics of high output, good product particle shape and low cost of wear parts.

The main crusher adopts an automatic control system, with fully automatic crushing process control, one-button automatic start and advanced fault diagnosis functions, which can realize overload or over-iron protection for crushing operations, and automatic compensation for lining wear. The main crusher lubricating system and hydraulic system are modularly designed and operate independently, which can realize the protection of oil temperature, flow, pressure, power and abnormal power supply.