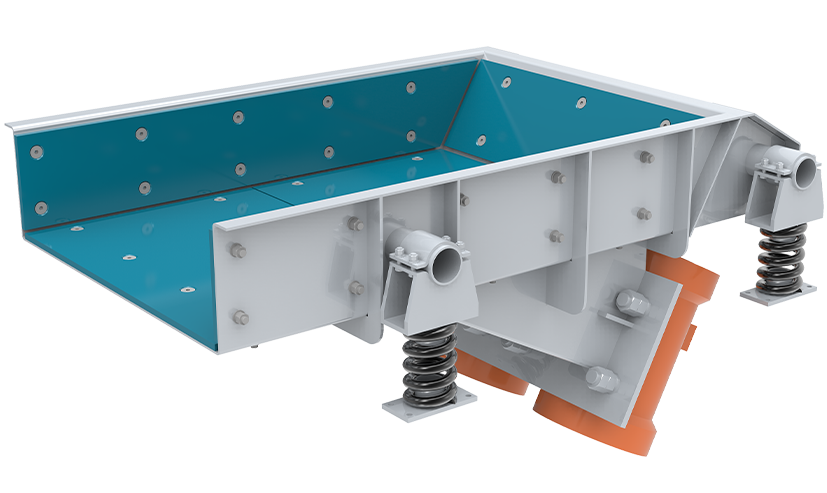

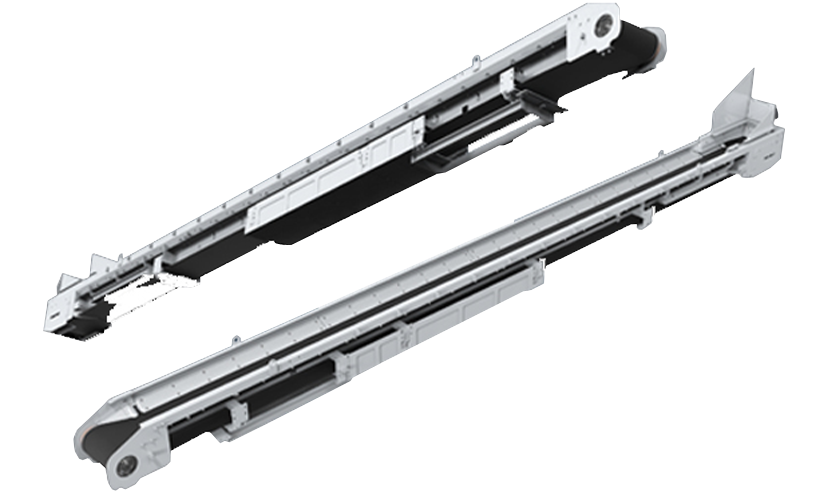

GZG Vibrating feeder is mainly composed of 2 sets of ZG type inertial vibrators, shock absorbers and feeding troughs. Since the 2 sets of inertial vibrators are symmetrically installed on the feeding trough body, the feeding trough body works in the direction of the resultant force. Simple harmonic vibration. The feeding process of the feeder is realized by the reciprocating linear vibration of the feeding trough along the inclined direction.

The machine adopts ZG type inertial vibrator as the excitation source, no rotating parts and few wearing parts. When installing, the tank body is properly inclined and installed (generally inclined downward by 10-15 degrees), which can greatly increase the feeding amount.