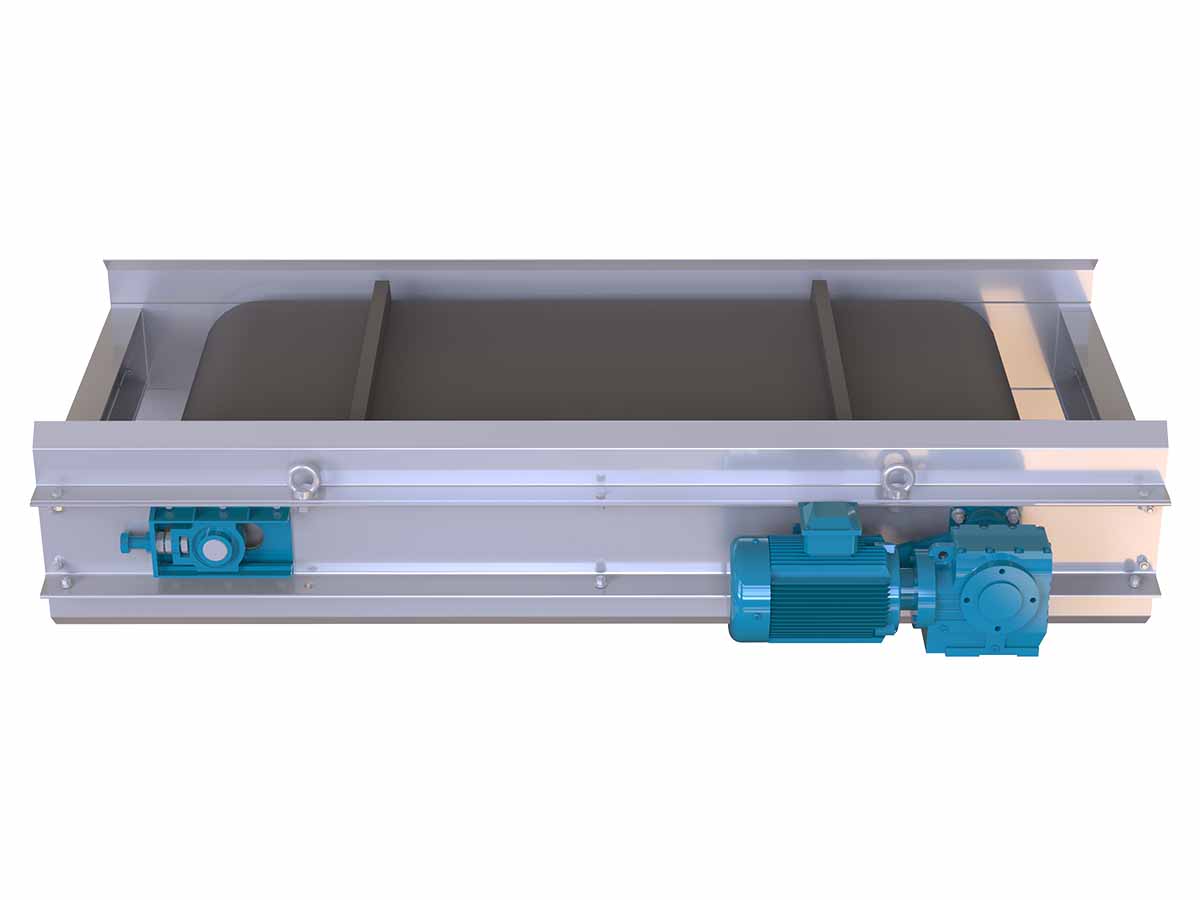

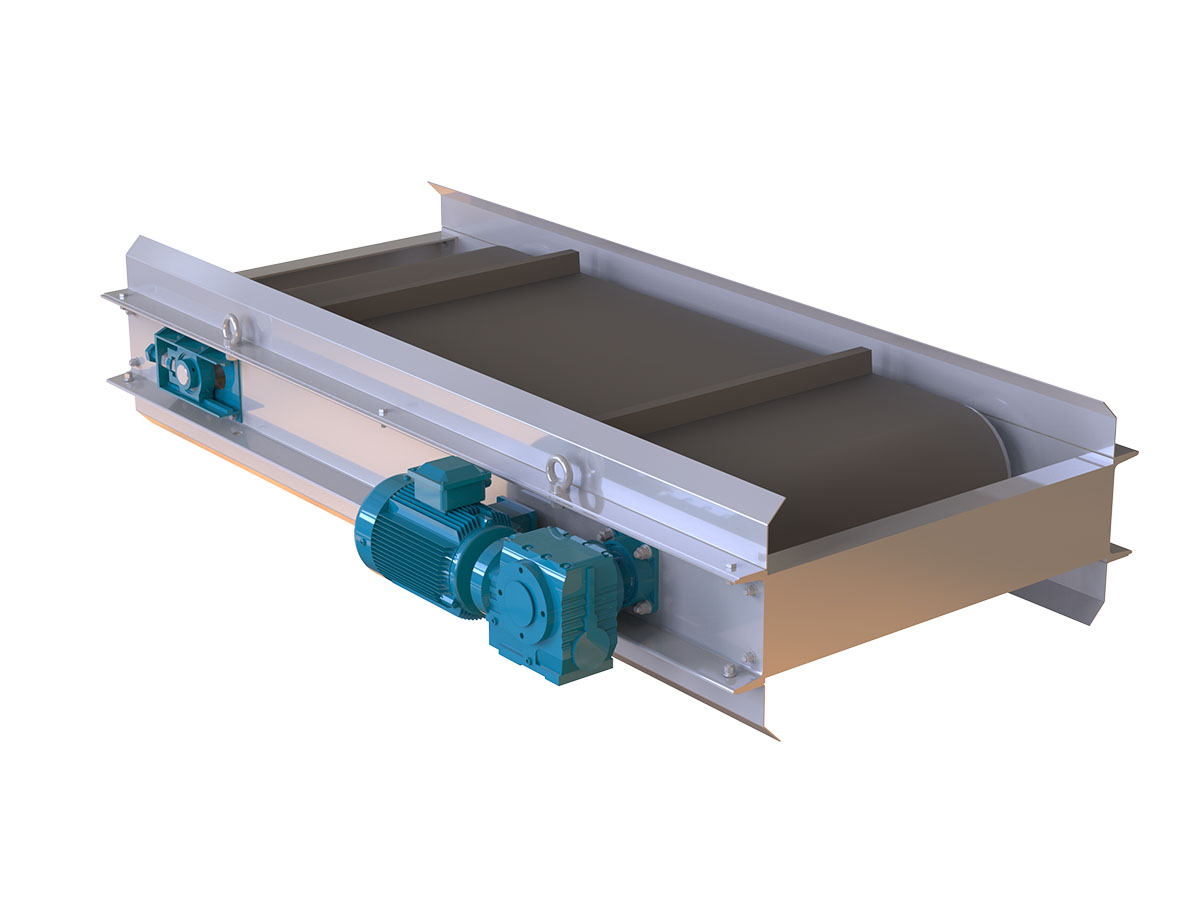

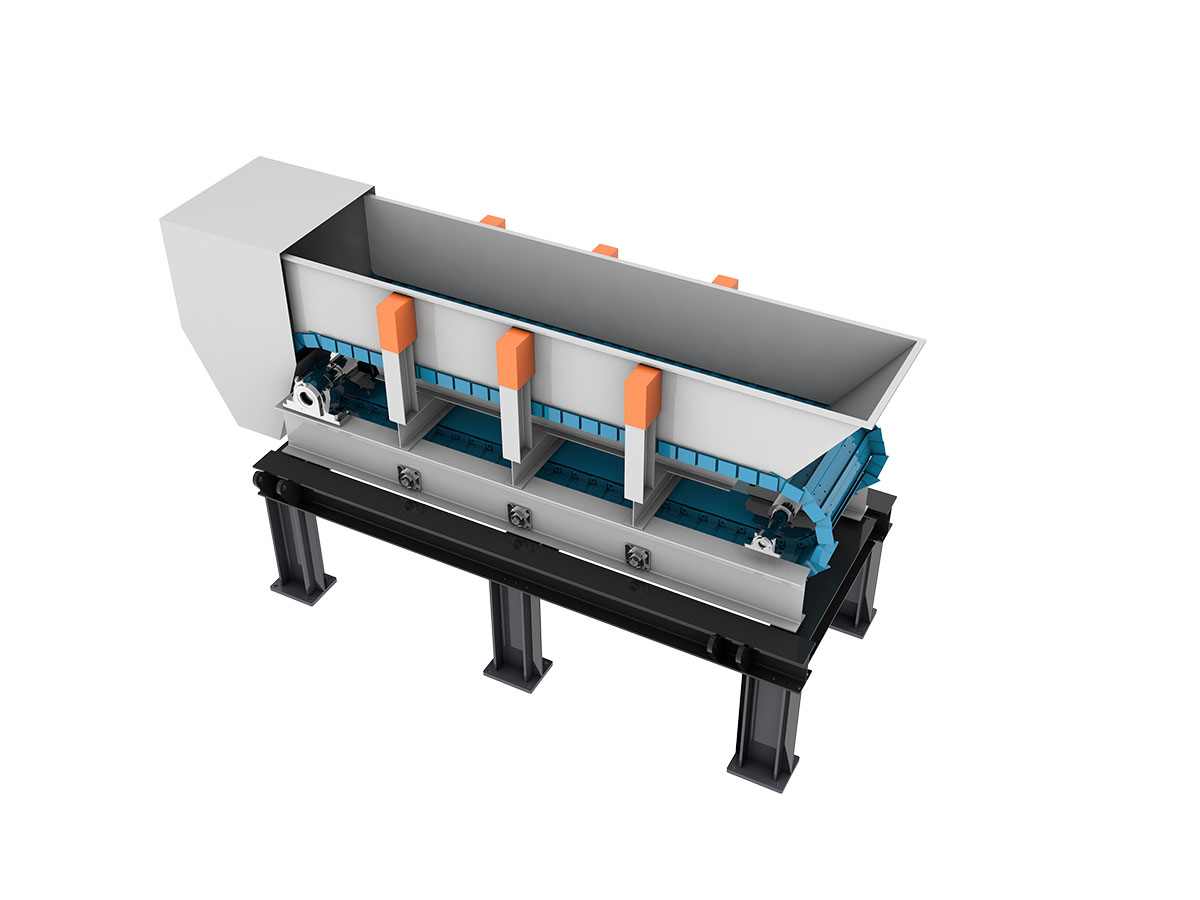

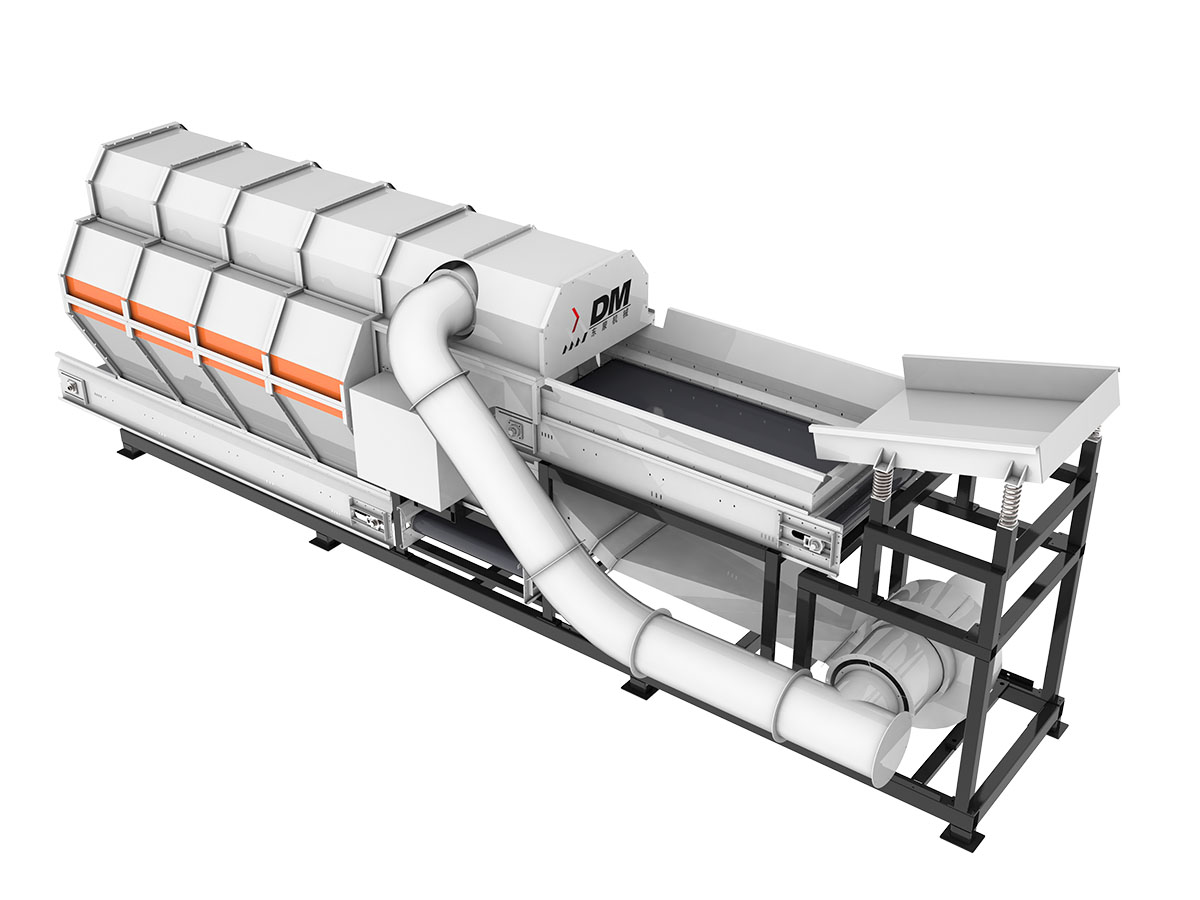

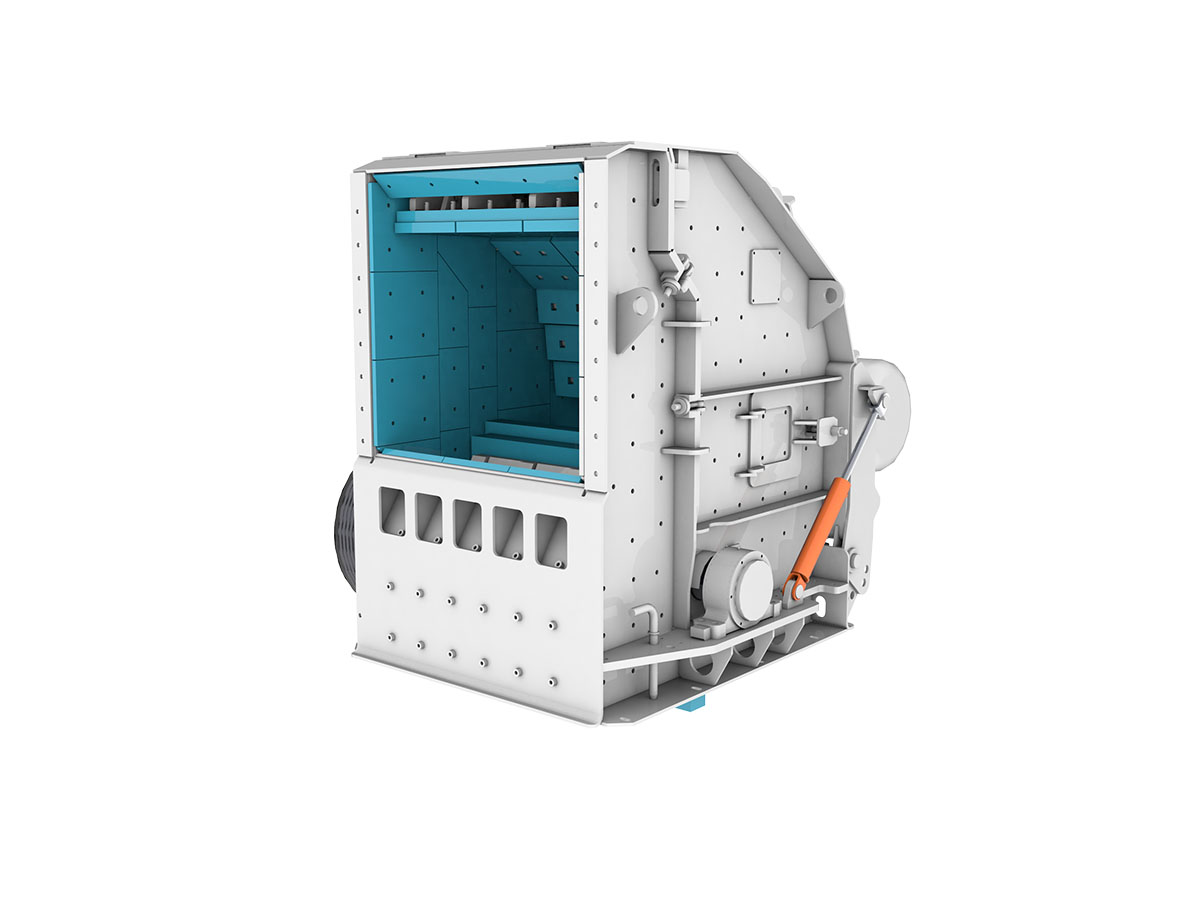

This is a self-unloading magnetic separator, spanning above a belt conveyor, used to separate ferromagnetic substances from materials passing through the conveyor. The machine consists of a high-performance rare-earth permanent magnet core, a self-unloading belt, a geared motor, a frame, and a drive roller, and is used to automatically remove magnetic substances weighing 0.05-50 kg from non-magnetic materials. Its internal magnetic circuit adopts a computer-simulated design and a sophisticated dual-pole structure, ensuring long-term trouble-free operation of the entire machine in harsh environments.

Engineered for operation in harsh environments, this system replaces belt drives with cycloidal reducers ,ensuring reliability, easy adjustment, and simplified maintenance. Automatically extracts ferrous contaminants from non-magnetic material streams.

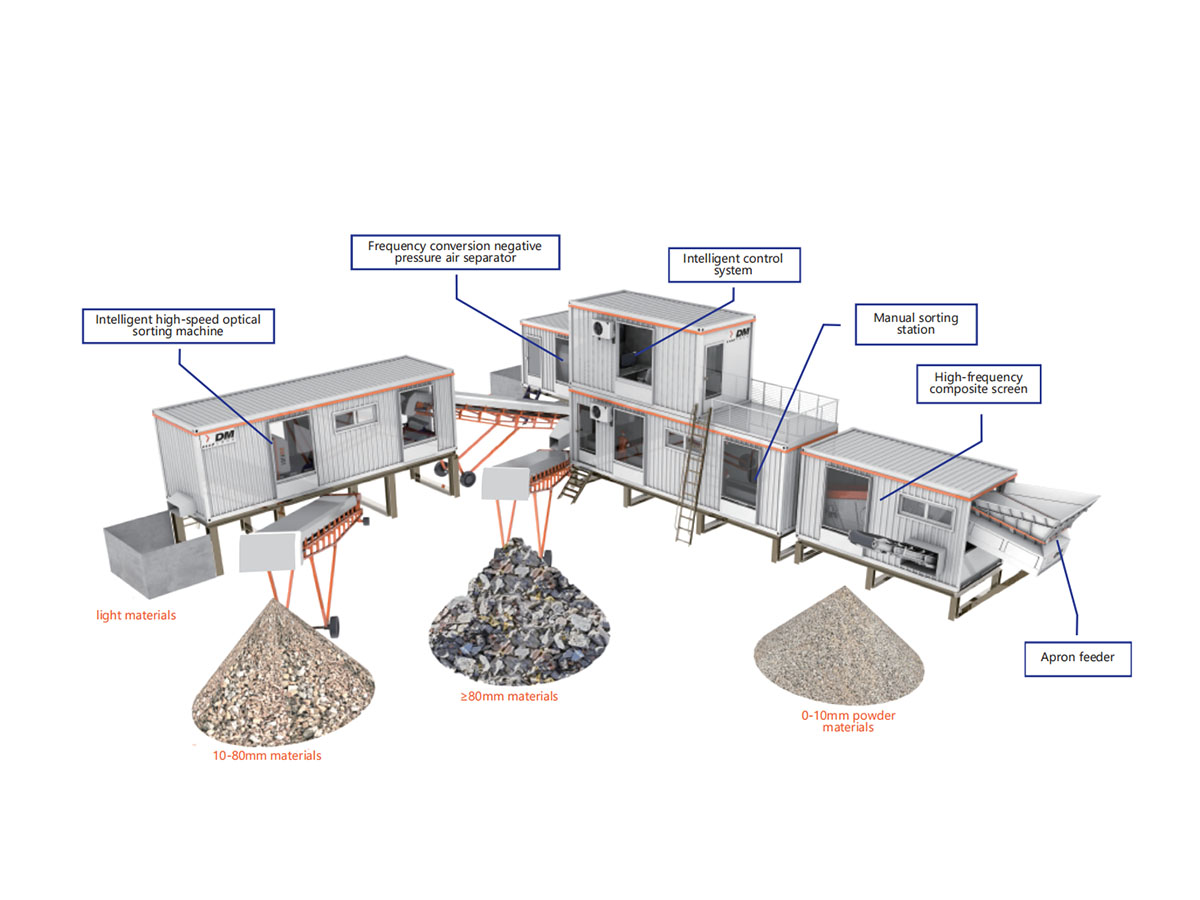

Performance Requirements: Efficiently sorts ferromagnetic substances from materials during transport; modular assembly is required; the material to be processed is construction waste.