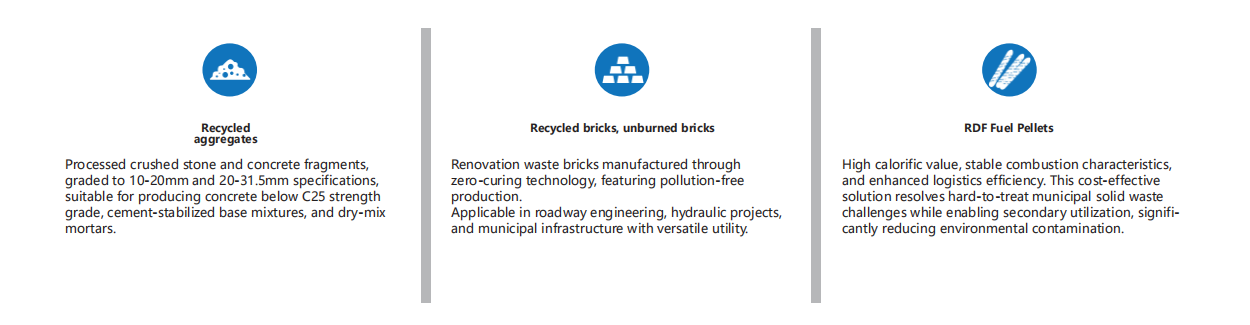

Pre-Sorting Stage: Large wood timbers and concrete blocks are manually or mechanically extracted before entering the system

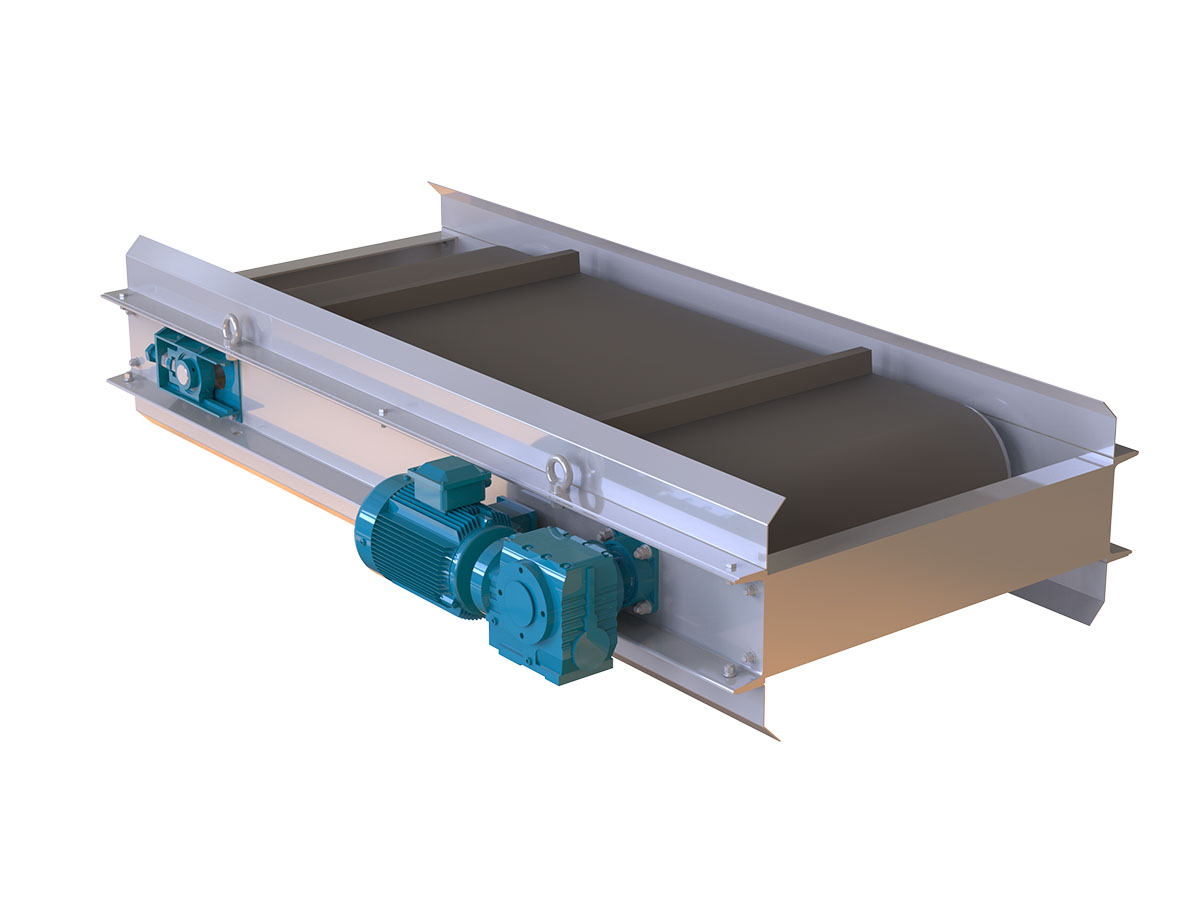

Feeding & Screening stage: Medium-duty apron feeders transfer pre-sorted waste to composite screens, segregating materials into: 0-10mm fines → Directly conveyed to stockpiles; 10-80mm mid-fraction → Iron removal → Downstream processing; >80mm oversize → Manual sorting

Manual Sorting Station: Operators extract lightweight contaminants (such as wood scraps, woven bags, and plastic films) from waste larger than 80mm, ensuring the purity of the coarse aggregate.

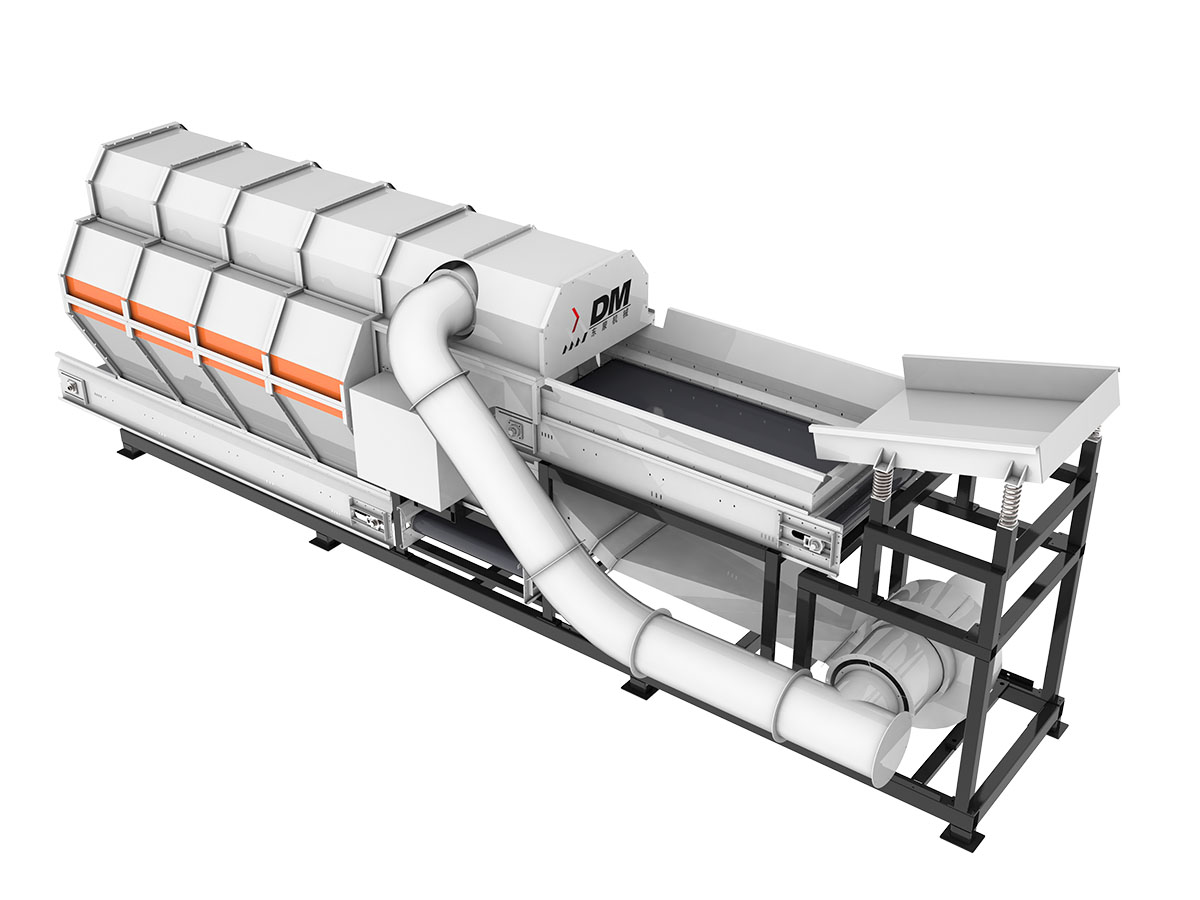

Air Classification Stage: Negative-pressure air separators process 10-80mm fractions, removing paper, plastics, and films through aerodynamic separation

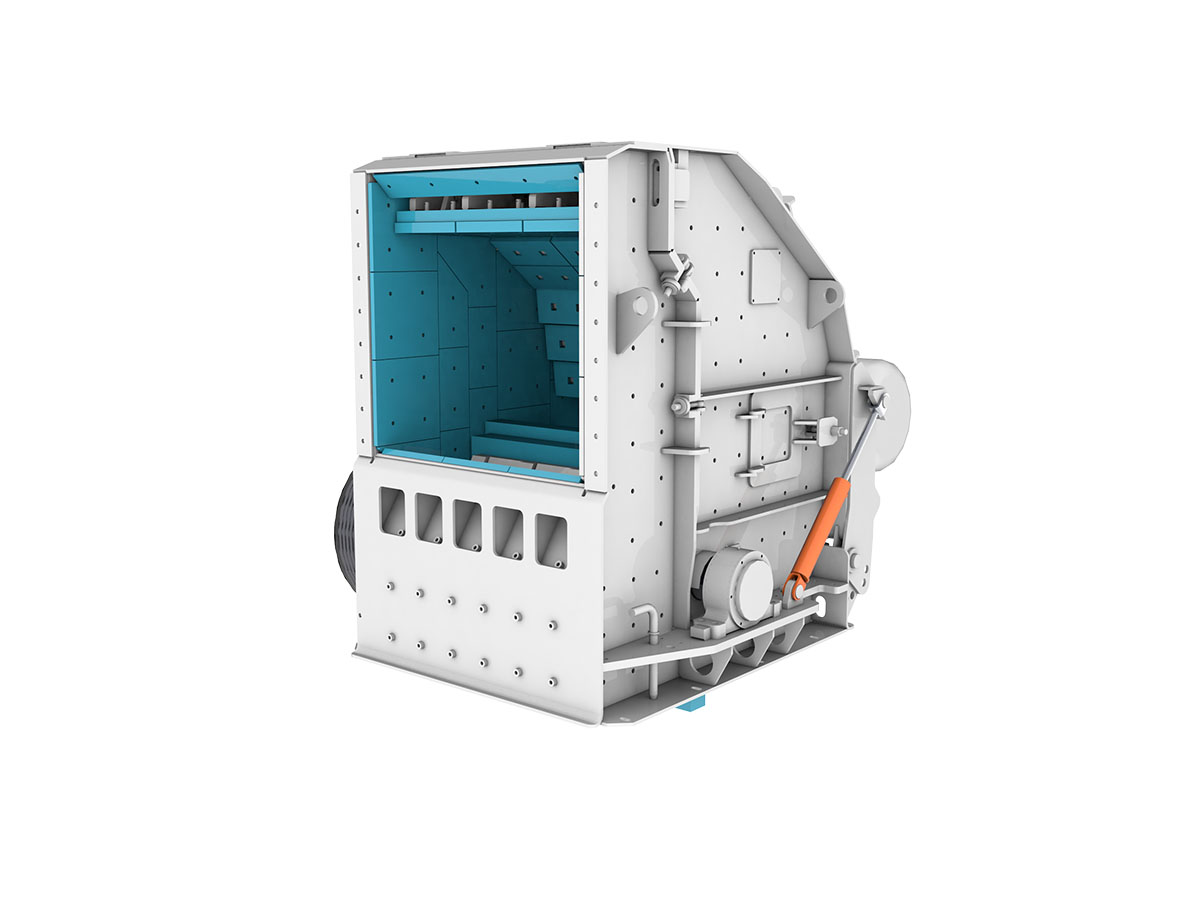

Precision sorting Module: Intelligence-enhanced optical sorters perform identification and ejection of residual contaminants in 10-80mm materials, achieving <5% impurity content. Final output: 0-10mm fine aggregates; 80mm purified coarse aggregates (optionally crushed via impact crusher); Ferrous metals; Lightweight fractions.

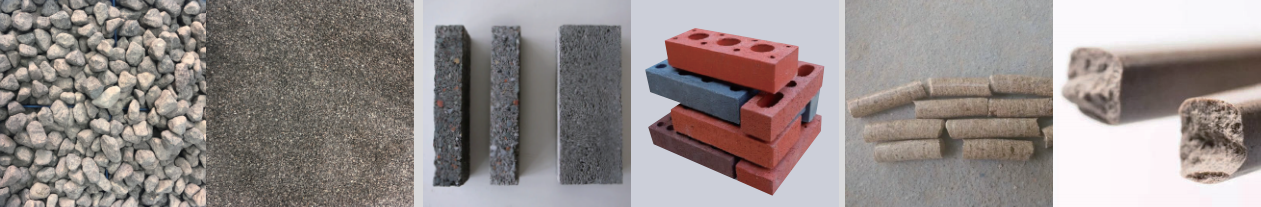

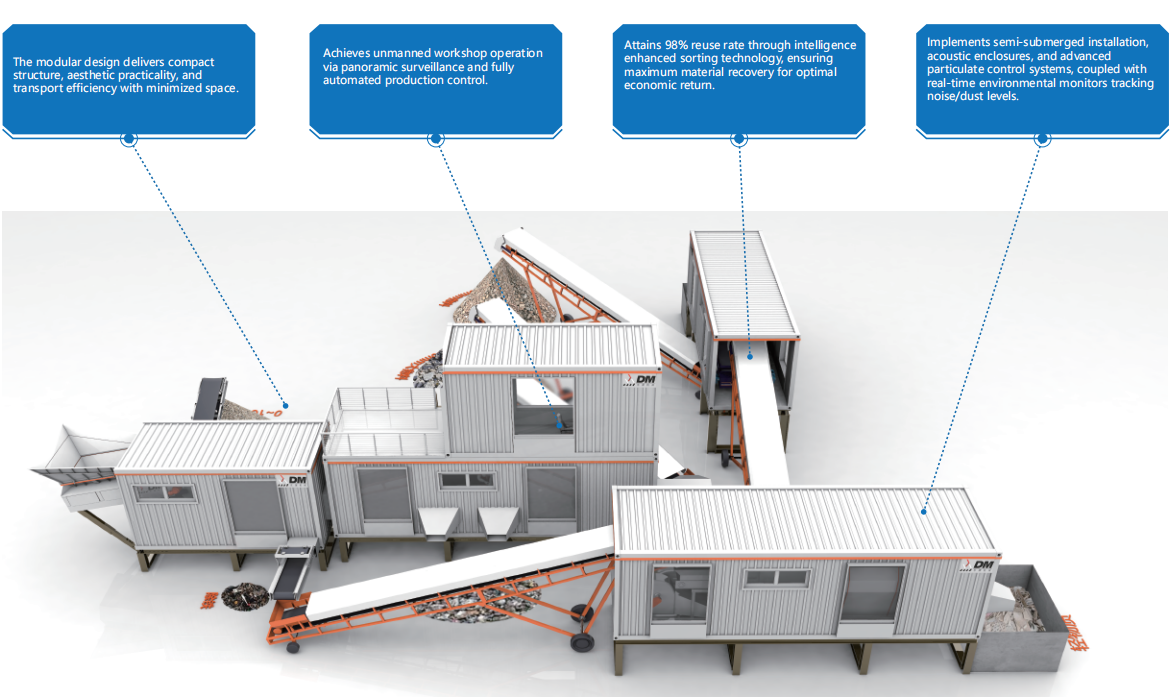

Solution advantage

The value of recycled resources